Electrical: Coil Packs

The Big Red team is known for trying many different racing setups, just like the known “drive fast and taking chances” saying implies. Big Red also is The Original Outlaw Racer™ ! But in today’s world, the BRC team needs Big Red to conform to many different rule books. Matching the best parts for specific races is an equation that constantly changes. With numbers from dyno test sessions, the team understood they were getting close to some limits and

needed to look in another direction for performance.

Eric and Brian suggested the use of coil packs. Since Big Red was using the Holley EFI Dominator ECU, a Holley Smart Coil Kit was put to use. Dave fabricated a simple mount for the coil pack-supplied bracketry, but also had to

fabricate mounts on a new set of valve covers, while Jack created a new wiring harness. The setup was used on the Elephant 2 598 engine, dyno’d, and put to the test at the Texas Mile in 2017. It was a great first test session, but more will be needed.

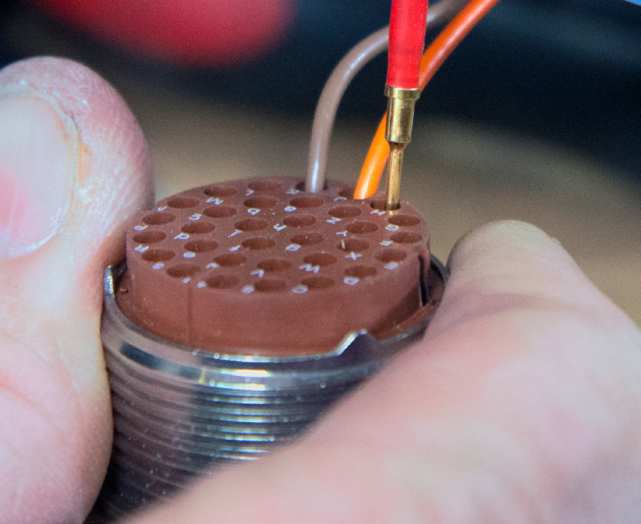

Jack planned the entire harness, so he knew exactly how many wires ran where. Some of the round Deutsch connectors were bigger than others. The first photo shows a flanged connector with 55 pins. The second round connector has 32 contacts. The wire contacts were inserted into a soft rubber seal, which surrounds the wire. Once Jack inserted all the contacts into the round connector, he wrapped the wires with Kapton tape to keep the shrink tubing and adhesive from getting on the wires. The next step was to slide the Raychem boot over the connector. Jack applied a bead of adhesive around the sealing area of the connector, then applied heat to the boot to shrink it around the connector. As the boot gets closer to the

wire, Jack applied more adhesive between the boot and the wire. The boots give a great weatherproof connection because they are sealed on both ends.

Jack conversed with Tim and the crew about all the necessary connections that need to be built into the automatic-transmission wiring harness. Once again, Jack used clear tubing hose to make the length of the wire harness for the transmission. Jack is well versed in all types of electrical connectors, but prefers Deutsch connectors. Incorporating multiple wires into one harness and one plug makes disassembly/service much more efficient when swapping equipment. All of these components used to be strewn about in the engine compartment. This well-designed box houses the blue Racepak V-Net sensor modules for fuel psi, water psi, intake air temperature, water temperature (two separate units), and transmission temperature, as well as a Universal Sensor Module (USM) for additional sensors. All these sensors receive signals from their respective engine and transmission components. The new box is mounted above the coil in the passenger footwell area on vibration-resistant isolator mounts. Jack and Dave discussed where to mount the V-Net sensor box Jack fabricated. In the end, it was mounted to a plate that Mark made that’s isolated with vibration-resistant mounts attached to the side of the engine-setback tunnel under the dashboard. The plate is also a mount for the single MSD ignition coil (when Big Red is only using a single coil to deliver spark for the engine). Another photo shows a later revision of the V-Net sensor box with the blue V-Net connector sticking out the side of the box. Originally, the V-Net connectors were run in a branch configuration. Later, it worked better in a pass-through setup

so the two connectors have an “in” and “out” of the box. The engine harness connects the engine to the Holley Dominator EFI ECU through the mil-spec connector on the firewall. The same harness can be used on both the naturally aspirated engine and the supercharged engine.

The lower mil-spec connector hooks the engine harness to the Holley Dominator ECU harness, while the upper harness connects the Holley Dominator ECU to the Rossler 4L80E transmission when the car is in Land Speed/Top Speed mode. There are left and right water-temperature sensors on the intake-manifold cooling system ports to make sure both sides of the engine are running equal temps. The 55-pin mil-spec Deutsch connectors with flanges are perfect for mounting to panels. These two are mounted to the firewall for the engine harnesses, and easily are accessed by removing the sealed panel that covers the cowl area. The mil-spec connector on the face of the firewall feeds the cooling fans, Fesler driving lights, and radiator spray-bar system when the car is in Road Race mode. The same connector also operates the Snow Performance water-methanol injection pump, solenoid, and its priming pump when Big Red is in Land Speed/Top Speed mode.